When you follow a recipe, the dosage of the ingredients is essential. If you add too much salt, you alter the expected result. Inventory management is similar, in the sense that you must properly do your quantities of products to achieve optimal result in the management of your warehouses. Following the implementation of the ABC methodology, companies often take advantage of this opportunity to review their inventory volumes. The methodology for this is called “Min / Max”. This seeks to quantify the desirable number of products to keep in inventory, based in part on the categorization of the product made during ABC analysis. An approach such as the “Min / Max” allows companies to ensure the health of their warehouse(s). It tends to minimize the risk of backorders without keeping excessive quantities of products on your shelves.

Despite the importance of having good warehouse management, it is common for companies to leave this aspect aside. However, the inventory can represent up to 20-25% of the costs of the business. It is therefore essential for a company, who is seeking to be competitive, to put the emphasis on good inventory management.

The impacts of poor inventory management

Establishing a “Min / Max” methodology makes it possible to respond to common problems found in many companies. Below is a list of some potential issues that you could have if these quantities are not properly defined/applied

Over stock

• High storage costs

• Need for more space

• Increased risk of losing inventory or pending orders

• Obsolescence in your products (if applicable)

• Risk of workplace accidents

Under stock

• Inability to deliver customer orders and a long waiting period

• Lower customer satisfaction

• Better business opportunity for the competition

• Complexity of the receiving and shipping processes

In detail, the three realities that we come across are most often :

Storage cost / Space requirement

Keeping a high level of inventory represents a significant loss to your space and your finances. An unnecessary amount of product equals losses in warehousing costs on top of being sleeping assets for your business. In addition, the space unnecessarily occupied for these products could be used for other business needs. We have already seen space savings of up to 40% as a result of inventory management projects among our customers.

Poor management / Loss of inventory

Once the “Min / Max” are defined for all products, it is much easier to keep control within your 4 walls and thus reduce the risk of inventory loss. With the ABC tool, which makes it easier to define a location by class (The “A’s” should be near the loading docks for example), it becomes much easier to locate a desired product. With your minimum inventory, you should always have a volume on hand in the space assigned to your product, minimizing the risk of spillage in your warehouses.

Waiting period

Unlike the issues of excess inventory, those related to backorders can dramatically increase delivery times for customers. In addition to being unable to deliver the product on time, the warehouse falls into a reactive rather than a proactive phase. Under the influence of urgency, this change often triggers unreflective decisions that are not optimal for the business. We must therefore be careful of side effects, where the fear of running out of stock leads to the purchase of huge quantities of products. This decision changes the inventory balance and you run into excess inventory side.

How to determine its optimal quantity?

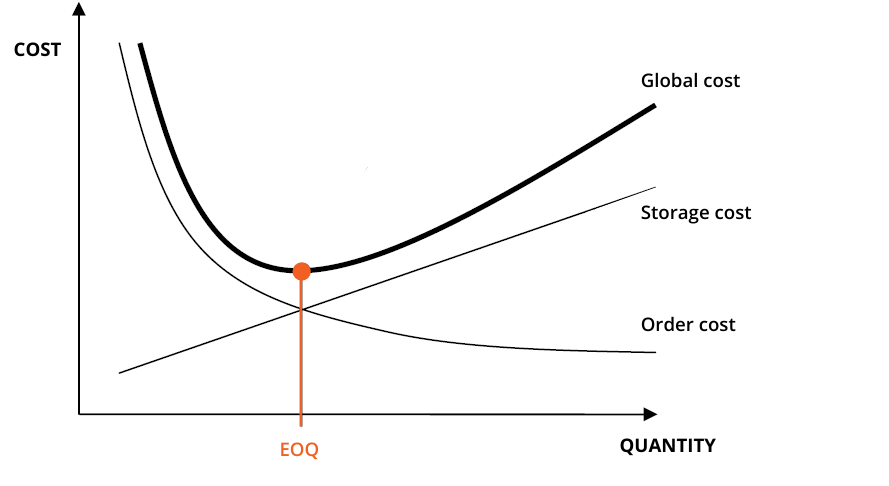

Now that you understand the importance of having a minimum and a maximum, here is how to roughly identify these values. The “Min” is based on the safety stock and the lead time of your product. Your “Max” is defined from the “Min” + the economic quantity to order (EOQ). This quantity represents the midpoint between the order cost curve and the storage cost curve.

Some of the parameters necessary for a good calculation of the EOQ are among others:

- Annual demand

- Purchasing cost

- Delivery cost

- Storage cost

Tools available to help you

There are several ways to calculate the “Min / Max” of a product, based on demand forecasts. It is possible that for some products demand follows a seasonality curve. Contrary to popular belief, your Min / Max doesn’t need to be static and can follow this curve as well. This flexibility allows you to be even more optimal in your approach. There are smart solutions to help you define these volumes according to your needs. In addition, it is essential to establish a good sales and operations planning (S&OP) strategy in your business. This allows demand to be aligned with supply capacity in the most cost-effective way possible and to control its history as well as sales forecasts.

Do not hesitate to contact us if you would like to learn more about the “Min / Max” methodology as well as the tools available to regain control of your warehouse(s).