Year

2023

Type of Project

Inventory

Savings

274K$

Directed by

Afef bouguerra

Audrey Lépine

Overview

Customer Presentation

Our client is a major player in the tire distribution industry in Canada. Having experienced significant growth in recent years, the company now operates around twenty distribution centers. Due to this rapid growth, our client aims to revisit its processes and operational management methodology to adapt to the new volume of business and operational complexity it faces.

Because of the nature of the product, the client experiences significant bi-annual seasonality in its operations. Furthermore, during these peak seasons, deliveries must be completed in less than 3 hours. Product availability is therefore extremely important during the high season.

Numerous flows existed between each of the depots to ensure tire replenishment or when products from an order are not available at the relevant distribution center. All these inventory manipulations and movements have an impact on the company’s operational performance and, consequently, on product profit margins.

Mandate

Conseil 2.0 was commissioned to assess the operational efficiency of this client’s supply chain. During this mission, after reviewing the processes and analyzing historical data, Conseil 2.0 identified opportunities for improvement and defined recommendations for best practices to be implemented.

Client's goal

The customer wanted to optimize its supply chain to reduce costs while maintaining or even improving service quality. The team wanted to improve operational efficiency across the organization and implement best practices for their needs.

Execution of the project

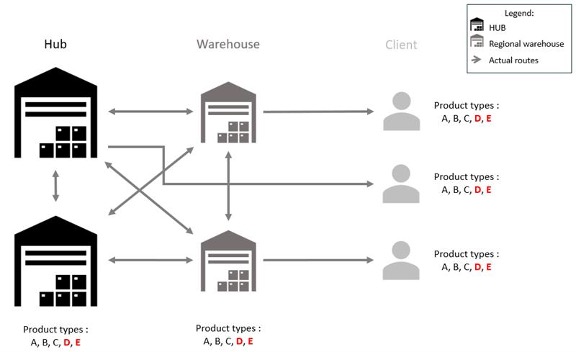

The customer had defined shuttle routes between warehouses, enabling products to be transferred as and when required. Some warehouses were not linked by a direct shuttle route. In these cases, products would make up to 5 stops before reaching their destination. Two types of product movement exist: “Order transfer” is a product movement triggered by a customer order with at least one product stop in a warehouse during the route, while “stock transfer” is a movement triggered by replenishment (prevention) parameters.

According to our analysis, 27% of orders were met by Order Transfers, with 32% of Order Transfers having more than one stop, and 24% of transfers concerned products later defined as “slow movers”. We therefore concluded that the number of movements needed to be considerably reduced, and that we also needed to review the strategic positioning of stock to meet demand by moving less stock between warehouses.

Conseil 2.0 decided to implement a Pareto classification to apply a strategic positioning of stocks and reduce their movement. In this case, intelligent inventory management increases the availability of fast movers in all warehouses and reduces the number of movements and space occupied by slow movers.

As we saw earlier, there are too many transfers between warehouses, and they take place between each of them. We therefore decided to define Hubs that would be the source of central replenishment. We started with a data analysis. Among the 20 depots, we highlighted 4 major ones that would also serve as Hubs. These Hubs were identified by considering 3 criteria: warehouse capacity, strategic location and sales volume in 2022.

Using Pareto classification, we established 3 categories of items A, B and C to identify fast movers vs. slow movers. The aim of this tool within the project is to reposition stocks more judiciously. This general classification also enables us to compare warehouses and identify the particularities (geographical, demand, supply, etc.) of each one, in order to adapt the inventory management strategy.

Due to the wide variation in demand between warehouses and the high number of SKUs, we have also classified by warehouse. This makes it possible to identify SKUs that have very few sales in the depots concerned. Therefore, 3 new categories C, D and E have been added to better represent slow-mover products that will have to be handled differently. Many non-value-added movements were made on these products. Demand being highly volatile and difficult to predict, they generated more handling, which had a significant impact on profit margins.

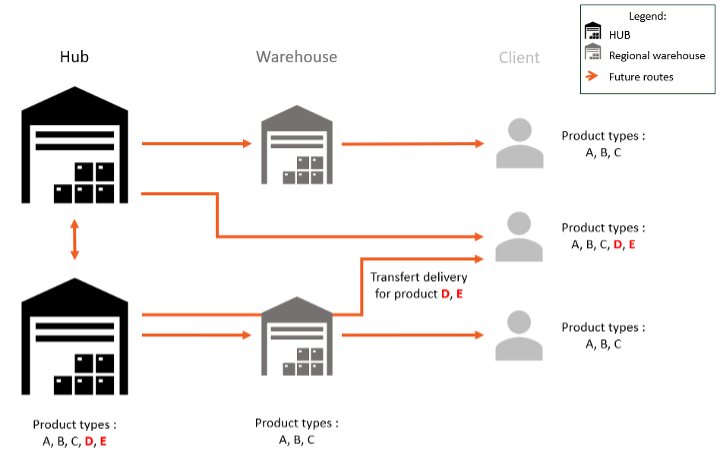

In order to optimize the company’s service level, for which availability is very important and seasonal, while limiting non-value-added activities, we proposed a class-based inventory management method. We have removed D and E products from small depots and concentrated them in hubs. C products will be partially stored in small warehouses and the remainder will be positioned in the hubs. This will increase A- and B-graded inventories in the smaller warehouses.

Product classification has also enabled us to review replenishment methods according to product. Fast-mover products will be replenished based on dynamic min/max parameters reviewed frequently according to the product’s season. For smaller demand products, initial replenishment at the start of the season will be carried out according to the above-mentioned stocking rules. In-season replenishment will be carried out through warehouses identified as HUBs only.

Results

- Partial centralization of category C and complete centralization of categories D and E in the hubs. Given that these products account for only a small proportion of sales, this frees up space in small warehouses for fast movers.

- By centralizing products and defining direct (non-stop) supply routes, the number of tire handling operations will be reduced by 990,576, the number of chain routes will be cut by 55% and this will reduce the distance transported by 15.4 M km annually. Considering that a truck emits 2.8kg of greenhouse gases (GHG) per liter of diesel consumed, our recommendations will reduce GHG emissions by 21,560 tonnes.

- Adjustment of service levels for categories A and B (increase in stocks in local depots and consequently service quality).

- Modification of replenishment methods by category: Adjustment of dynamic min/max parameters to consider seasonality and replenishment strategy. (Centralized or by warehouse).

- Thanks to a balance between increasing the availability of the vast majority of products and reducing stock movements between warehouses, Conseil 2.0 was able to achieve operational savings of $724,000, as well as a significant reduction in GHGs.

Route diagram before the mandate

Route diagram after the mandate